about the quality of printing ink

The authors:SHANGHAI SHUNGE Release time:2015-07-17

上一篇:good quality good price high speed ink printing slotting mach 下一篇:about The front paper printing slotting machine-ink printing

about the quality of printing inkcarton machinery factory:A, printing the processing of the thief thief is most common in the production of corrugated carton is also the most difficult to eliminate quality problems, the reasons are: paper in

about the quality of printing ink

carton machinery factory:A, printing the processing of the thief thief is most common in the production of corrugated carton is also the most difficult to eliminate quality problems, the reasons are: paper ink absorption performance is poor;Plate dirty;Cardboard some dust, dust, etc.To these questions the traditional processing method is artificial change box, or increase the artificial clean version of the frequency.These methods will play a role in objectively, but not improvement effect after change box, and easy to cause the loss of efficiency;Wipe edition will also cause the waste of water, electricity, artificial.

Through long-term observation analysis, the writer think that in the process of equipment installation, maintenance and management, the key to solve printing thief lies in the dust.Dust is the main source of single pole points when the paper, based on this, the author two years ago after the cardboard production line electrical brain cross-cutting knife and printer paper department has installed the electrostatic suction aspiration device, use the hair drier, in front of my computer cross-cutting knife to monolithic knife hidden in the grooved as "paper about dust blowing out or blow off, and then after computer cross-cutting knife paper frame in the use of electrostatic inhale confetti suction dust collection device.In the printer paper feed aprons and feeding wheel clearance in inhale dust on the board by using electrostatic dust collection, with good quality printing surface clean dust-free, under such conditions, the cardboard into the printing roller, ink on the barrier-free, and ink evenly.After the improvement, the product printing effect is greatly improved, and fundamentally overcome the dust caused by printing the thief.

Second, the overprint of processing

Now more and more pay attention to the artistic design, commodity packaging stereo feeling, make consumers feel the perfection of the purchased goods from the outer packing.To achieve this purpose, packaging and printing multicolor printing must be used, namely, multi-color overprint.

In overprint process, often appear after the color with the color overlay position or orientation, the printed pattern can reflect the design of product packaging effect, widely divergent, even completely destroy the image of the product.

According to this particular problem, the company over a period of time into the scene investigation and study, to reflect electric control speed to fit tolerance precision machinery, has carried on the detailed calculation, several improvements to the existing equipment, related equipment maintenance measures at the same time.

Cylinder phase 1, improve the positioning precision

Brush roller printing phase positioning using encoder and counter control, if the precision of the counter is too low, will cause the encoder position is inaccurate and press go.Reflect the rate of 3 k, but often in the positioning error of plus or minus 1 mm, after discussions with Taiwan electronic company, producing 5 krcounter, printing roller positioning error was reduced to + / - 0.4 mm.

2, timing, lubrication, detection of mechanical drive

In the process of paper, if the mechanical transmission can not keep good and balanced running, makes every board arrived at the location of the changes, resulting in a printing and set and therefore the correct maintenance of equipment and inspection measurement is very important.Can make daily boot commissioning check list before starting work, including lubrication and maintenance.Making paper feeding wheel at the same time, the limits of the paper ring wear, unqualified must turn mill, plastic bags or replace again, overcome the cardboard in the walking process go a, inclined a wait for a phenomenon.

3, equipped with suction paper

Traditional printed on the printing machine adopt, can only use paper feeding wheel transmission board, and a new printer by printing, suction on board transfer of advanced technology.Suction paper use wind to cardboard adsorption on the transmission wheel, its suction uniform, not to walk, not oblique, and sucked flat curved paperboard, counterpoint, when printing ink on more evenly and more smooth.

Three, printing ink bad treatment

Bad ink on paper and offset problem, on the device and inking roller technology deal with the problem.

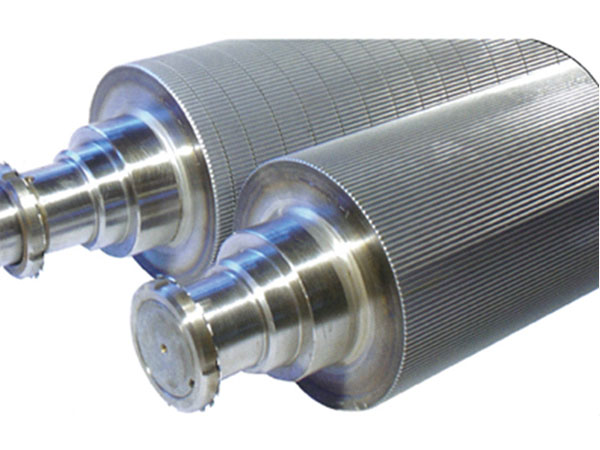

Inking roller adopt the anilox roll, in high standard carton printing, use the anilox roll of 250 lpi above, the mesh is the most easy to ink residue jams, resulting in uneven ink, ink is not enough, the ink on the resulting in uneven ink, ink is not enough, the phenomenon such as black light.Black on the traditional way is to use clean water roller, water scrubbing inking roller or detergent scrub, effect is not too ideal, on a new ink roller to use less than a month, effect clear as before.

The company through long-term grope test, it is considered that the several method can effectively solve adverse effects of printing ink.

The relevant information: